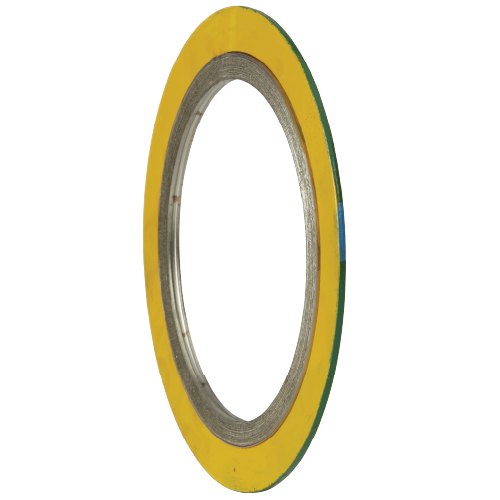

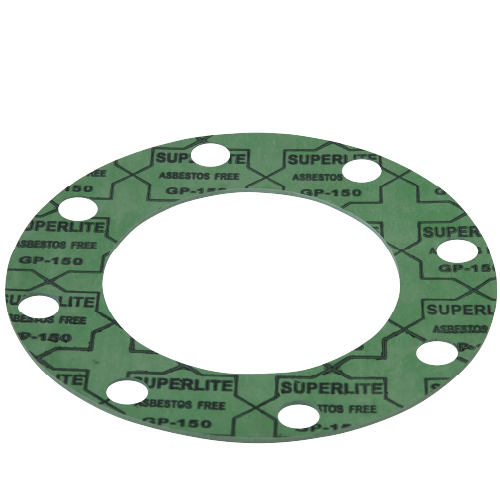

GASKET COMPRESSION & CHOICE OF THICKNESS

| Nom. Thickness | Compressed Thickness |

|---|---|

| 2.5 mm(.098 in) | 1.9/2.1mm(.075/.085 in) |

| 3.2 mm(.125 in) | 2.4/2.6mm(.095/.105 in) |

| 4.5 mm(.175 in) | 3.2/3.45mm(.125/.135 in) |

| 6.4 mm(.250 in) | 4.6/4.8mm(.180/.190 in) |

| 7.3 mm(.285 in) | 4.7/4.9mm(.185/.195 in) |

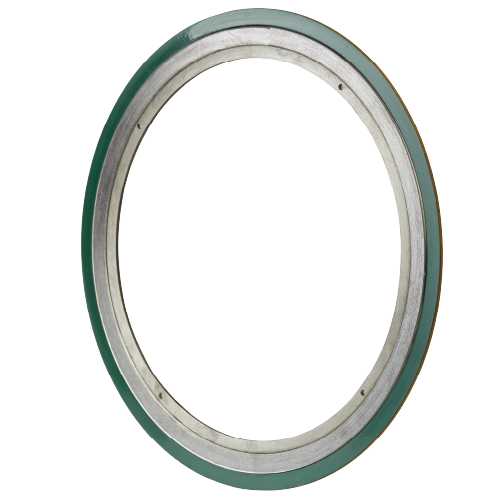

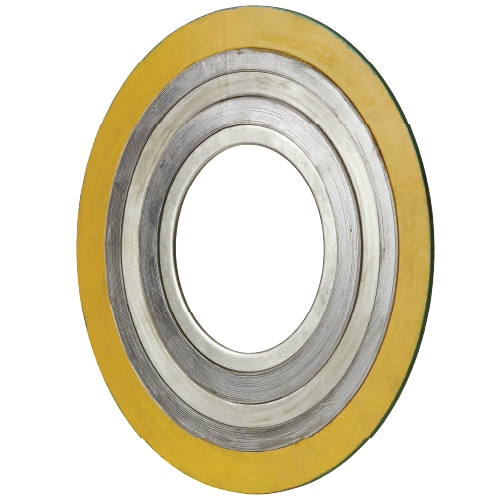

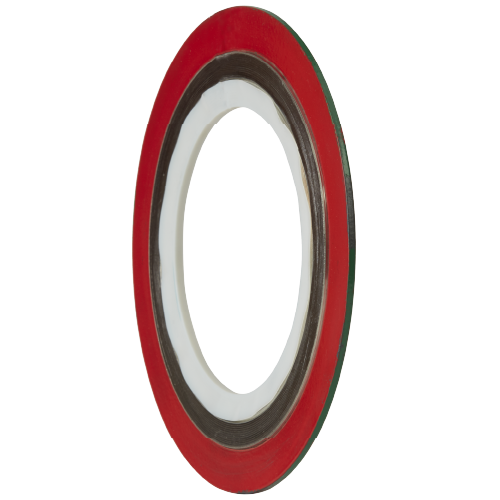

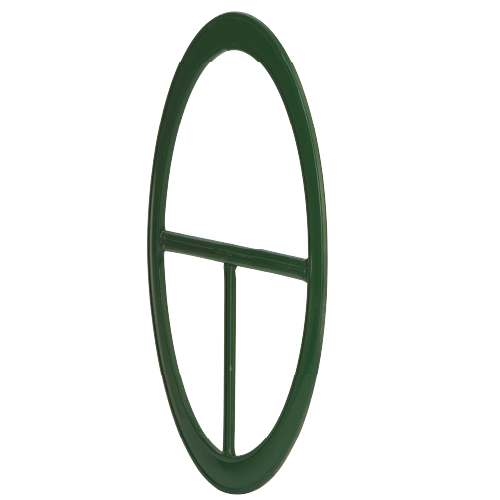

INNER AND OUTER RING

Carbon Steel, Stainless Steel 304,304L, 316,316L,316Ti,321,347, MONEL® 400,Inconel® 600,625,800, Incoloy® 800, 825, Nickel 200, Titanium, Hastelloy, Copper, Inconel X750.

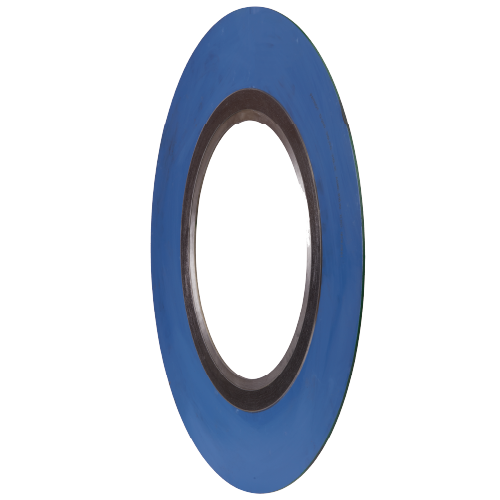

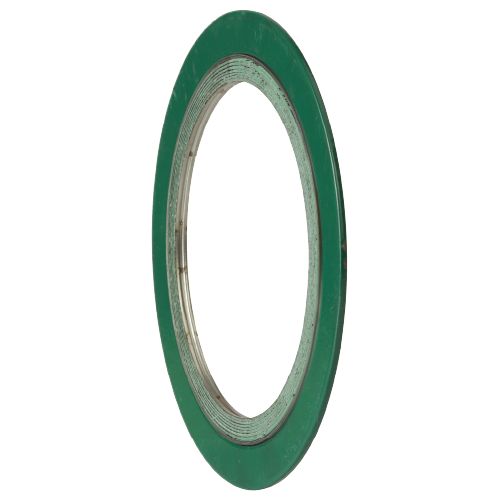

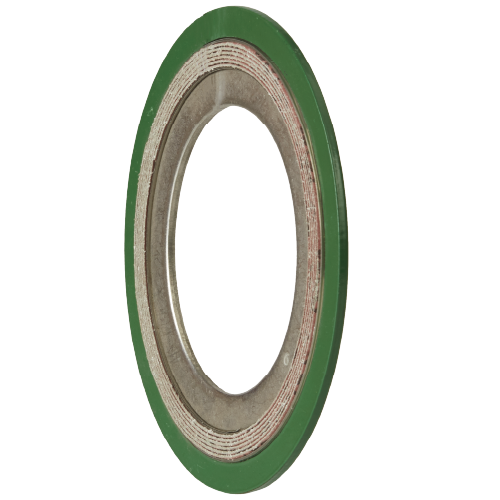

SPIRAL WOUND GASKET SIZES

Size & Shape as per Prevailing International standards or Customer needs can be produced.