Ring Gaskets are designed to seal by "initial line contact" or wedging action between the mating flange and the gasket. By applying pressure on the seal interface through bolt force, the softer metal of the gasket flows into the imperfections of the harder flange material, creating a very tight and efficient seal.

Standard Style R Ring Gaskets are manufactured in accordance with both API 6A and ASME B16.20 size/ratings. Available in both oval and octagonal configurations, both types are interchangeable on the modern octagonal type grooved flanges.

The Octagonal cross section has a higher sealing efficiency than the Oval cross section and is therefore preferred. These gaskets are manufactured as per API 6A / ASME B16.20 to suit API 6B and ASME B16.50 flanges.

The oval section ring gaskets were originally designed for the now obsolete round bottom groove. Both the Oval and the Octagonal cross section are interchangeable on the flat bottom groove design. These gaskets are manufactured as per API 6A / ASME B16.20 to suit API 6B and ASME B16.50 flanges.

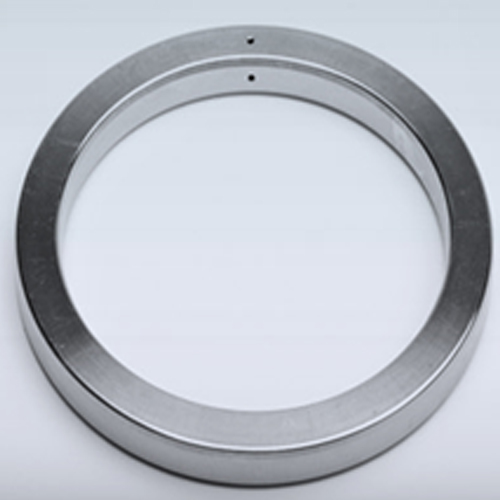

BX Ring Gaskets are designed for pressures up to 20,000 psi, suitable only for use with API type BX flanges and grooves. The gasket has a square cross section with beveled corners. All BX sizes have a pressure passage hole to equalize pressure across sealing surface.

The RX is a pressure energized version of “R” type flat bottom groove. RX Ring Gaskets are designed for pressures up to 5,000 psi, they are pressure activated ring gaskets designed to use the fluid pressure to increase sealability. These gaskets are manufactured as per API 6A / ASME B16.20 to suit API 6B and ASME B16.50 flanges.

IGP is able to provide safe, dimensionally and functionally interchangeable subsea wellhead, mudline and tree equipment within the scope of API. The performance requirement of pressure integrity, thermal integrity, material choice along with no observable leakage allowable are met with these sealing desires. To distinguish from topside Ring Type Joints the suffix “s” is used to indicate the additional pressure passage hold in the ring cross section. This is to indicate the additional requirement to prevent pressure lock when connections are made up underwater.

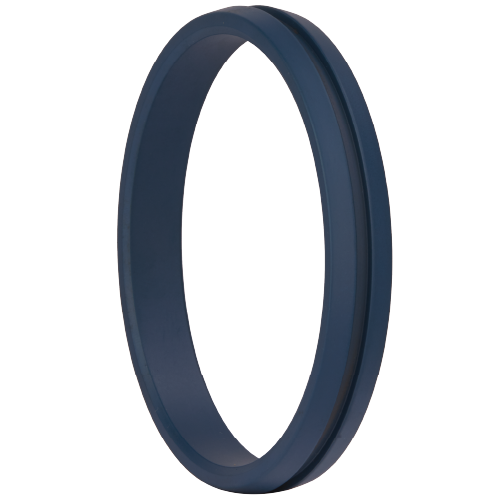

IX Seal Ring IX Seal rings are designed to be used in Norsok Compact Flange connections (NCF). Available in different materials, IX rings are supplied with colour coded PTFE coating to denote base material supplied. Identification markings are on the inside of the ring in accordance to NORSOK L-005 standard.

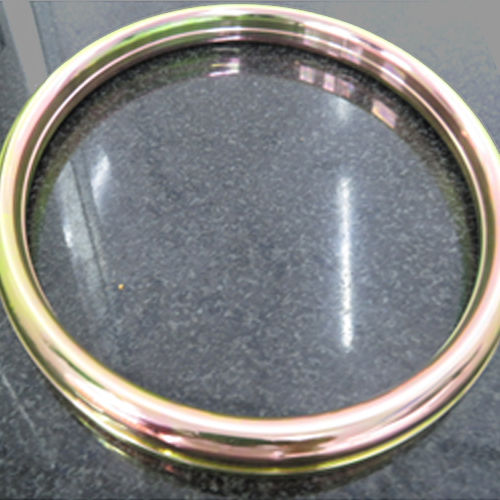

IGP Lens Rings, manufactured in accordance with DIN 2696. Lens Rings have a spherical surface and are suitable for use with conical flange faces (other styles are available on request).

This is Ring Gasket totally enclosed in a nitrile rubber coating. The Ring Gasket material is usually soft iron or low carbon steel. This type of gasket has three main functions:

For critical and non-standard applications, IGP offers a range of specialized Ring Gaskets to suit the needs of the petrochemical industry.

These are combination rings which consist of two different sizes having the same pitch circle diameter. They are used for sealing Ring Gasket flanges where the mating flanges have different ring groove diameters. Transition Ring Gaskets can be manufactured from standard materials, as well as high nickel alloys. Transition Ring Gaskets are available with either oval or octagonal facings and are not involved by the API specification.

Spiral wound gaskets, Ring Gaskets, Solid metal gaskets, Non metallic gaskets, Insultation kit gaskets, Heat Exchanger gaskets, Kammprofile Gaskets, monolitihic insulation joints, Valve Components clamp.